Damp-Proofing Concrete And Watertightness

- Sam Ellis

- Sep 23, 2016

- 3 min read

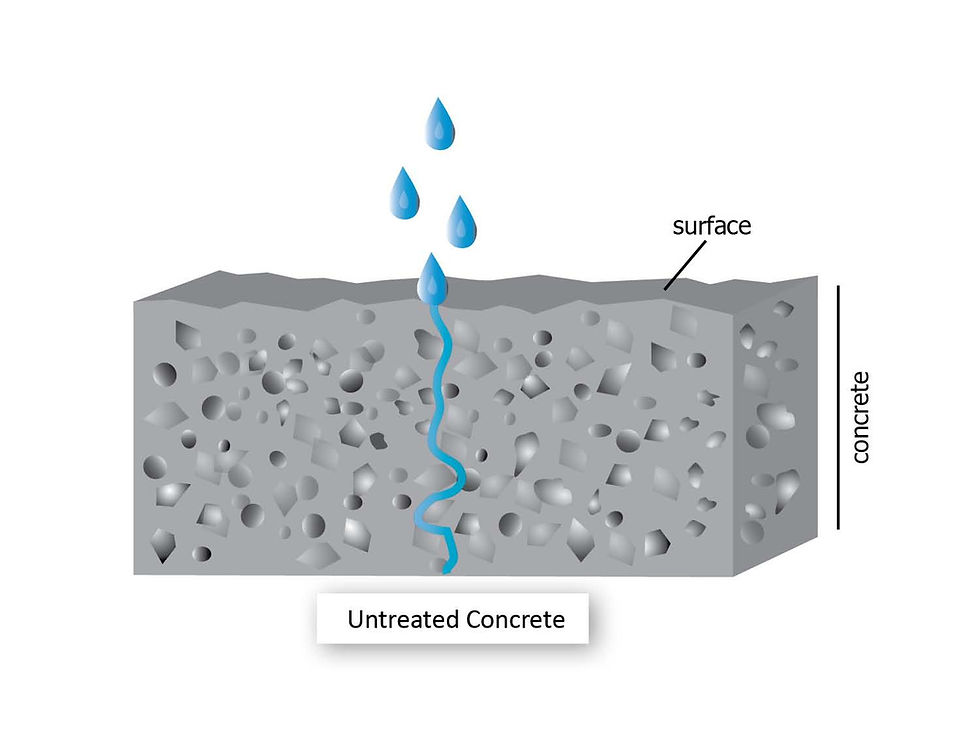

To ensure the concrete is workable on site, most concrete contains more water than is required to simply hydrate the cement. As this concrete sets and hardens, this excess water leaves the concrete and creates a network of fine cracks and internal pores which act almost like a sponge. How then, do you get a mix that ensures water won't leak into or through your concrete structure?

First things first: because concrete is an inherently porous material it can never be 100% waterproof. Instead, the technical term used to describe a resistance to water permeability is "watertight".

To achieve the level of watertightness for a given application, the following factors need to be considered:

Appropriate material selection and suitable concrete mix design

Adequate structural design

High quality construction

Getting the right mix

Achieving a suitable mix for your job requires balancing the needs for durability and workability with the requirement that the mix is watertight. To achieve a watertight mix, the following is recommended:

Using admixtures (including super-plasticisers) to reduce the amount of water required to achieve a required slump/workability (see AS 1478.1) or to reduce permeability (AS 1478.17)

Minimal water-binder (water-cement) ratio while ensuring compaction, workability and hydration remain adequate

Using materials in the mix which limit shrinkage strain (while ensuring adequate structural integrity)

Using environmentally appropriate mixes taking into account temperature, humidity etc. to ensure cracking does not occur

Some notes on Admixtures

There is no admixture currently available that will make concrete fully waterproof according to AS 1478.1 Appendix F. There are however a number of permeability reducing admixtures available on the market including:

Inert pore fillers

Chemically-reactive pore fillers

Water-repelling substances

Water-reducing and air-entraining substances

Special purpose admixtures

No admixture will achieve improved performance alone and they need to be combined with:

Effective structural design

Quality concrete mix design

Low water-cement ratios

Good compaction using an immersion vibrator

Adequate curing practices

High quality construction

Construction techniques and design

We'll be putting together another article on good concrete practice on building sites however a few key pointers to keep in mind when it comes to ensuring watertightness:

Adequate compaction is critical: compact concrete in shallow layers using an immersion vibrator to eliminate voids or honeycombing. Avoid excessive localised vibration as this may lead to bleeding

Correctly specified reinforcing will minimise cracking: cracking is a major source of water permeability in many instances

Use suitable formwork: formwork should have a smooth finish; tight, waterproof joints; taped joints where modular formwork is used; use surface-release agents which will allow air-bubbles released during compaction to free the mixture

Construction joints should be planned for positions where their weakness won't have an adverse structural effect: the joint surface should also be sand-blasted or water-blasted to remove laitance and expose coarse aggregate (with loose material washed away)

Adequate curing for at least 7 days (or as specified in the appropriate Australian Standard): make sure curing compounds used and techniques applied are appropriate for the conditions and design requirements

Post-construction treatments

Beyond the above methods, many finished surfaces are treated with sealants or membranes to improve watertightness. Common treatments include:

1. Waterproofing membranes

Cement-based render with or without chemical admixtures may enhance the water-repelling properties and/or reduce permeability

Resin-based render

Continuous vapour-proof membranes

2. Crystalline Sealers

Materials that fill the pores in concrete with crystals

3. Surface coatings

Relatively thick surface films can be applied to concrete using polymer binders coupled with pigments and fillers. Coatings vary in their UV resistance, water resistance, flexibility and carbon dioxide resistance

4. Joint waterproofing

Sealing joints can prevent degradation of your concrete's watertight properties. There are a variety of methods available include silicones, PVC, urethanes and metal strips.

Further information

Australian Standards

Note: Watertighting concrete can be complicated. MaterialsLink advises that you speak to a technical expert if you are uncertain about the right way to achieve what you need for your job. Our suppliers can provide detailed information on specialist concrete mixes if you need it: get in touch with us for assistance.